The project team for the interior design consisted of the owner of the project, China Resources Land (CRL), interior designer and BIM consultant (1), Beijing Original Consociation Interior Design Co. Ltd. (OCD), and the construction team. Switching from the old mantra of “you need to design in 2D and re-model with BIM”, the design team used SketchUp throughout the entire project to create lightweight models and communicate intuitively in 3D, saving time and money.

.webp)

The Chengdu Hotel needed to be built in time for the opening of the Chengdu Universiade Sports Center in 2021, leaving only 17 months for completion. With a tight construction cycle, strict cost control, and high-quality requirements, CRL knew they needed a lightning-fast design workflow. Although CRL had never done a hotel project with life-cycle BIM, they pivoted to this new process. Life-cycle BIM involves all disciplines and stakeholders and is the 3D design and management of a building from concept to demolition. CRL could test out new workflows on this hotel project because it was owner-led, and they supervised all stakeholders from design to construction.

The final building is 61,000 sqm (656,600 sq.ft.), including three towers, a podium, a banquet hall, 351 hotel rooms, and a basement. In December 2019, the concrete foundation was poured; by May 2021, this colossal project was finished, with a total construction time of 17 months. In comparison, 32 months is typically the time it takes to design and build a hotel, meaning this project shortened the construction cycle by nearly 50%. Closeout was 7-8 months, compared to 12 months for similar scale hotel projects, which shrank closeout by 42%.

.webp)

.webp)

.webp)

.webp)

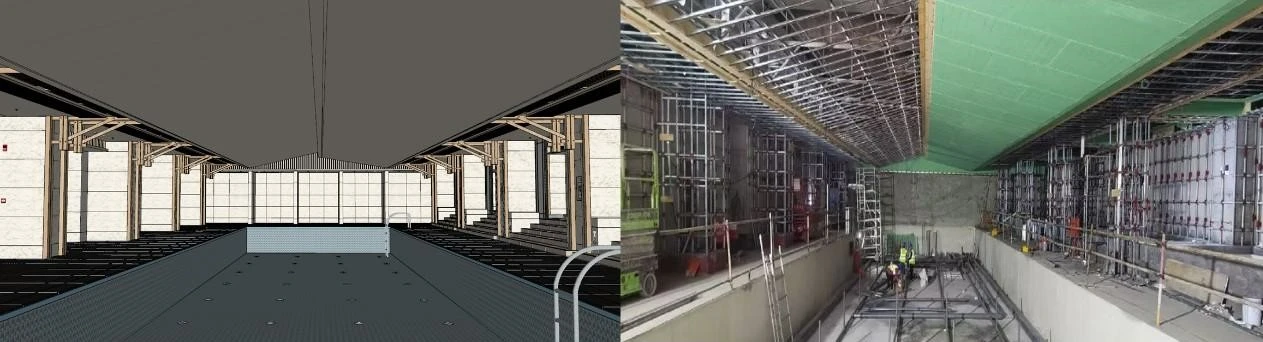

This project used a Trimble scanner to capture millions of points around the project under construction. Due to site conditions and the project's sheer scale, the point cloud scan for the hotel under construction was compiled in building segments, separated by floor. Then the structural dimensions and elements from the Interior Schematic Design Model were adjusted based on the point cloud data to form an accurate basis for detailed interior and MEP (mechanical, electrical, and plumbing) models.

The team synchronized models across disciplines using the point cloud data captured by the Trimble scanner. Due to this synchronization, materials, costs, standard processes, and other information were consistent. The unified standards saved time and money for the client.

At the beginning of the design, the hotel had hundreds of room types for more than 300 rooms, which was a massive headache for the construction team. Thinking quickly on their feet, the design team implemented two procedures to reduce construction time and ensure an accurate build. One was standardizing the room design, allowing prefabricated components in factory production. This standardization saved construction time, labor, and cost and reduced embodied carbon and waste. The other was to use Trimble point cloud scans to create accurate digital twins and Trimble Robotic Total Station layout for precise construction.

The Trimble Robotic Total Station (RTS) is a tool for accurately laying out the intended design on-site, delivering increased efficiency and precision with layout tasks. The hardware works alongside Trimble FieldLink software, which runs off a tablet that hosts the most up-to-date SketchUp model of the hotel. By selecting a layout point on the tablet, the Robotic Total Station orients and projects a laser beam to the relevant direction and angle within seconds. Laying out the site based on the BIM model improved the positioning accuracy of the masonry and finish materials and ensured the site was the same as the 3D model. The team visualized the layout using virtual reality mobile apps for bonus points.

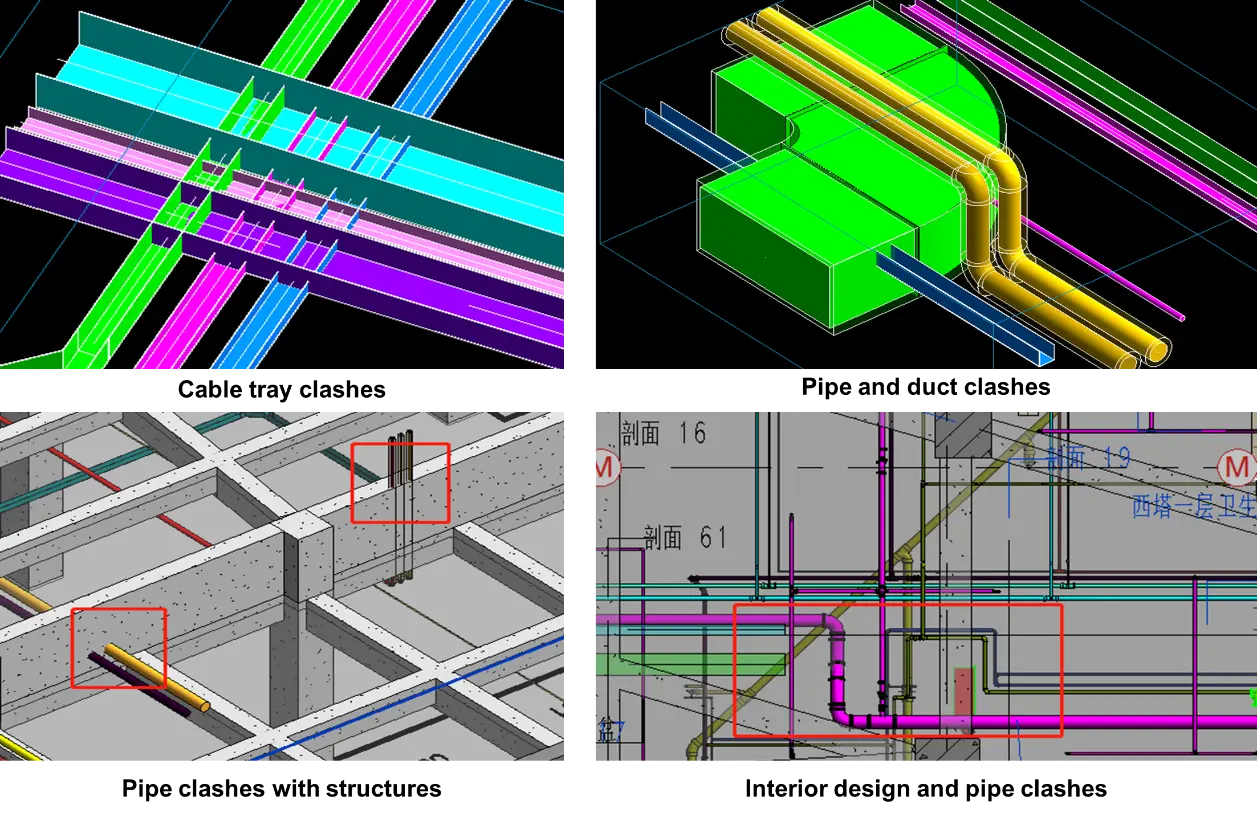

Clash detection, the process of spotting issues between different disciplines’ models, is an essential application of BIM. It enables the project team to solve potentially costly inconsistencies within the BIM model before on-site construction begins.

The benefits of the life-cycle BIM process are clear; scanned point clouds of a building’s structure can be easily layered onto the interior design and MEP BIM models. Leveraging Trimble Connect’s clash detection feature to assess all these layers ensured that the hotel’s overall MEP assemblies meshed seamlessly with the interior ceiling elevation requirements.

How does a traditional workflow for calculating BOMs look? Picture this: quantity surveyors sort through a thick stack of drawings on the table late at night. They tediously start calculating and recording the length, area, and volume data of each drawing by hand.

But the team didn’t want to stick to traditional for this project. With the BIM modeling process used for the Chengdu Hotel, the material coding and dimensions were input into Dynamic Components in SketchUp. The different materials corresponded to different calculations to generate volume or area from the model. Using SketchUp’s Generate Report feature, the quantity surveyors could export material properties and quantities in one click to get the BOM. By connecting design and construction, the SketchUp model fulfills the ultimate purpose of BIM and serves as a digital twin for future operation and maintenance.

The team set up construction and installation sequencing using the BIM model and LayOut, SketchUp’s 2D documentation tool. Contractors placed orders for components by material type from the BIM model, and then the components were prefabricated and installed on-site. Because the LayOut drawings are synced with the SketchUp model, all drawings remained consistent and up to date throughout the construction process.

The BIM model guided the construction of the hotel’s interior and multi-discipline coordination, reducing construction time and increasing efficiency. It also served as a guide for procuring construction materials, mitigating potential safety risks on site, assembling with flow line processing in factories, reducing the material scrap rate, and meeting the government’s prefabrication rate requirement for the building. The SketchUp model was given to the factory manufacturers to guide the customization process of materials. As shown in the figure below, the BIM model drove the layout of finishes, achieving zero cutting, zero scrap, zero pollution, and low carbon because dust wasn’t produced on site. These processes saved time and staffing, reduced costs, and increased efficiency. Going forward, projects by CRL and partners will use this new workflow for hotel fit-out material assembly.

The design team didn't waste time downloading and copying files by interacting with SketchUp extensions throughout the cloud-based collaborative design platform. The highly-coordinated, all-discipline design process helped stakeholders communicate the project timeline, share and transmit data, and reduce the errors and omissions in traditional construction drawings.

SketchUp is an excellent design modeling software and BIM tool for many domestic and international projects. According to the design team for the Chengdu Hotel, SketchUp is simple and lightweight, and when combined with other Trimble software and hardware, it’s the ultimate design package.

With only three years of accumulation and validation, CRL and OCD (with other partners) have achieved something spectacular – nearly 50% construction time savings, significant cost savings, increased safety, and carbon reduction. The design team cautions that it takes a few projects to incorporate these workflow improvements fully. However, with this technology, you can achieve true life-cycle BIM for design and construction by changing and upgrading your workflow.

Powered by Froala Editor

Subscribe to receive blog updates using your address.